Supply Change: our commitment to sustainability

FM Logistic Ibérica following its sustainability strategy, Supply Change, designs and manages responsible supply chain models promoting changes in consumer habits and in our…

Em April 28, 2022

FM Logistic Ibérica following its sustainability strategy, Supply Change, designs and manages responsible supply chain models promoting changes in consumer habits and in our…

Em April 28, 2022

FM Logistic Ibérica following its sustainability strategy, Supply Change, designs and manages responsible supply chain models promoting changes in consumer habits and in our society.

It is therefore responsible for decarbonising its logistic activity in order to be carbon neutral, create positive impacts for the planet and be fully sustainable in its operational activity. Our most important project is to promote green hydrogen and lead the change in the logistic sector. Furthemore, to mark a turning point in the way other companies operate and reach the goal of zero emissions.

It consists of the implementation of a hydrogen station at the Illescas logistic platform. In this way, it launched the first integrated green hydrogen project in the Spanish logistics sector. The hydrogen produced in the hydrogen station can be used both for internal use vehicles (forklift) and external use (vans or trucks). In this way, we will be the first carbon neutral warehouse using hydrogen. The hydrogen station is already in our warehouse awaiting the final checks before it can be put into operation.

The hydrogen station will be able to dispense up to 45kg/week of green hydrogen and refueling a vehicle can be completed in just 1-2 minutes. Due to its innovative nature, the hydrogen station project is supported by the Centre for the Development of Industrial Technology (CDTI) and the European Regional Development Fund (ERDF).

Another curiosity of the project is the origin of the hydrogen. We say that FM Logistic has integrated green hydrogen because it obtains the energy necessary to carry out the electrolysis (the process of separating hydrogen and oxygen atoms) by means of photovoltaic energy. This energy comes from the solar panels on the roofs of its Illescas warehouse. In this way, only oxygen is expelled into the environment, an indispensable gas in the environment and a necessary material for the life of human beings. On the other hand, the main raw material for the hydrogen station is water (H2O), a low-cost renewable resource and source of energy.

This logistics platform in Illescas has a standard multi-client corporate design adapted to the most modern European regulations. It also stands out for being a LEED Gold certified building (Energy Efficiency Certification, eco-efficient and sustainable building). Likewise, it has been awarded as the “most sustainable and environmentally friendly company” at the recent awards of the Toledo Business Federation (FEDETO).

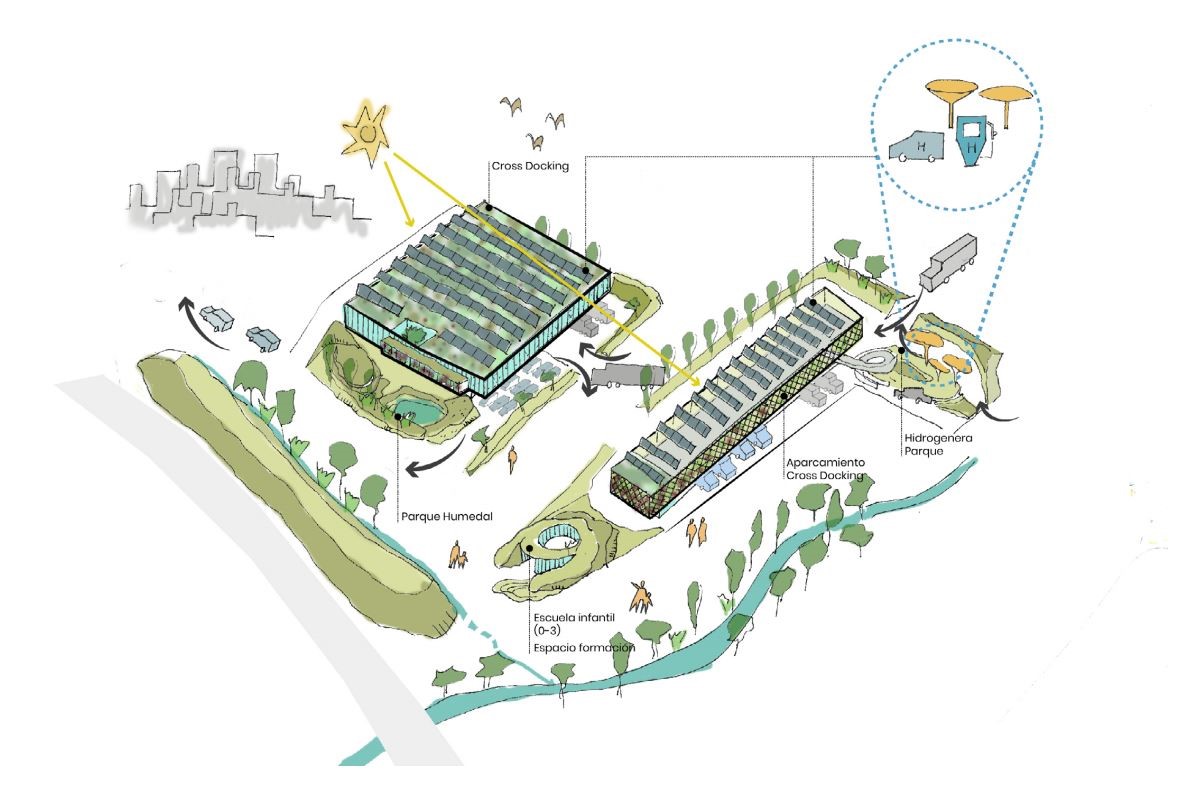

The immediate landscape of La Atalayuela in Vallecas is made up of anthropogenic origin hills and are the result of decades of waste accumulation. his is a clear example of how, without good management, they can become a very serious environmental problem.

Our project Hi Life, considers this problem as an opportunity. By creating a regenerative and fertile nature from excavated land from the construction site. A nature of 9,000 m2 of groves, wetlands, landscaped areas and rainwater ponds. It will reproduce six of the natural ecosystems protected and recognised as belonging to this area by the Community Habitats Directive, with species adapted to the site and which collaborate with each other, requiring little maintenance.

This natural infrastructure will support a business ecosystem. This will drive the incipient development of La Atalayuela towards its most sustainable form, and will be determined not only by the requirements of C40, but also by the needs of the programme, which will revolve around two buildings for logistics activity.

The first building will have large cross-docking spaces to develop urban logistics and office space. Moreover, the second building will be used for sorting goods.

Therefore, the two buildings will be built to LEED environmental standards. They will have glass facades and green roofs that are very different from the opaque enclosures typical of industrial buildings. On the roof of both buildings will also be a photovoltaic power plant with almost 13,000 m2 of floor space.

This use of space frees up sufficient surface area to locate the aforementioned green areas. Hi Life is committed to social integration in the southern area of plot B and to sustainable mobility with a hydrogen station on the northern side of the same plot.

Indeed, one of the focus points of this project is the production of green hydrogen from self-produced photovoltaic electricity and reused water from the activity of both plots. It will be dispensed in plot B both to vans and forklifts, as well as to external vehicles.

The Shine Fleet project (Hydrogen-based Technology Solutions for smart and sustainable mobility of autonomous heavy-duty fleets) will address the main research areas related to hydrogen generation in a decentralized way. For use in heavy-duty trucks.

Partially supported by the CDTI (Centre for the Development of Industrial Technology). Within its “Missions” programme, the project has been selected within the “sustainable and intelligent mobility” mission. The project will address all aspects of the hydrogen value chain in mobility, which are currently less developed. This will enable the performance of such integrated solutions to be improved in the future.

Supported by the Ministry of Science and Innovation and subsidized by the CDTI, Técnicas Reunidas, together with the rest of the consortium, made up of FM Logistic, Avia Ingeniería, Carbotainer, Cikautxo, Idneo and Fractalia, will be supported in very specific areas of research by the Institute of Chemical Technology (UPV-CSIC), Tecnalia, Complutense University, Autonomous University, the National Hydrogen Centre and Eurecat.

FM Logistic has started testing the first 100% electric truck developed and manufactured in Spain. The truck, designed for urban logistics, was tested in the distribution of goods for an IKEA shop in the center of Madrid.

The first 100% electric truck has been developed within the framework of the European project CIVITAS ECCENTRIC. Madrid City Council, FM Logistic, the Polytechnic University of Madrid and Avia Ingeniería y Diseño S.L. have participated in the project.

The purpose of this European project is to improve urban mobility. This is one of the great challenges we face in Europe. It is aligned with the European policies agreed in the Paris Agreement. In the agreement, the signatory countries take up the challenge of limiting global warming and recognise the need for a progressive and effective response to the pressing threat of climate change.

This 12 ton truck designed and developed by Avia ingenieria y diseño SL is 100% electric; it provides a range of 120km and full battery charge in 6 hours.

The first operational tests were carried out in the supply operations of the IKEA urban shop in Goya Street in Madrid, whose stock comes from the Swedish multinational’s Alcorcón shop.

Join our change!

Preencher o formulário