Supply chain management as a key to success

The management of our supply chain is a fundamental part of business success, as it is responsible for coordinating and optimizing all the activities necessary to bring a product…

On April 11, 2023

The management of our supply chain is a fundamental part of business success, as it is responsible for coordinating and optimizing all the activities necessary to bring a product…

On April 11, 2023

The management of our supply chain is a fundamental part of business success, as it is responsible for coordinating and optimizing all the activities necessary to bring a product or service from its origin to its final destination. When done efficiently, an ideal supply chain management can bring many advantages to companies, such as cost reduction, increased efficiency, greater customer satisfaction, improved decision making, greater flexibility to adapt to market changes, among others. In this post from FM Logistic, we will delve into the importance of supply chain management and how a good strategy can be key to business success.

Supply chain management (SCM) is a key process for any company involved in the manufacture, distribution or sale of products or services. It is a global strategy that aims to coordinate and optimize all the activities necessary to bring a product or service from its origin to its final destination. This involves efficiently and effectively managing all processes related to materials procurement, production, storage, distribution and delivery, ensuring maximum efficiency and effectiveness at each of these stages. Good SCM management not only improves the quality of the product or service, but can also reduce costs, improve customer satisfaction and strengthen the company’s competitive position.

Properly managing the supply chain is important for several reasons. First, good SCM management allows for better planning and coordination of activities at each stage of the production and distribution process, which can reduce costs and improve efficiency. Second, proper SCM management can improve product or service quality by ensuring that high quality materials are used and safe and effective production and distribution practices are followed. Third, efficient SCM management can help improve customer satisfaction by ensuring that products or services are delivered at the right time and with the expected quality. In addition, proper SCM management can also improve the company’s ability to adapt to changes in the marketplace and respond effectively to customer demands, which can strengthen its competitive position.

Organization

In this phase, the objectives are defined and the necessary plans and strategies are established to achieve efficient and effective SCM management. This involves defining the roles and responsibilities of each member of the SCM team, as well as identifying the suppliers and strategic partners needed to carry out supply chain management. In addition, this phase also establishes the processes and systems needed to monitor and manage the SCM, which may include the implementation of inventory management systems, the implementation of information technologies for supply chain management, and the definition of policies and procedures for risk management.

Suppliers / procurement

The supplier or procurement phase is another key stage in supply chain management. In this phase, suppliers are identified and selected to provide the materials and supplies necessary for the production of the company’s products or services. Once identified, contractual agreements are established and the terms and conditions of the contracts are negotiated, including the price, quality and quantity of the materials and supplies to be delivered. This phase also establishes the necessary procedures and systems for managing the relationship with suppliers, including performance measurement and risk management. Good management of the supplier or procurement phase can ensure that the company has access to the necessary materials and supplies at the right time and at a reasonable cost, which can improve efficiency and reduce production costs. In addition, proper supplier management can also ensure the quality and consistency of the materials and supplies delivered, which can improve the quality of the final product or service.

Manufacturing

In this phase, the production of the company’s products or services is carried out using the materials and supplies previously acquired in the procurement phase. During this stage, it is essential to ensure the efficiency of the manufacturing processes, as well as the quality and safety of the final product. To this end, various production management techniques can be used, such as Just in Time (JIT) or Lean Manufacturing, which allow for more efficient production and cost reduction. In addition, the implementation of quality management systems and the adoption of good industrial safety practices are also important aspects in the manufacturing phase of SCM. Good management of this phase can ensure that products or services are produced efficiently, safely and with the expected quality, which can improve customer satisfaction and strengthen the company’s competitive position in the market.

Logistics distribution (delivery and return)

In this phase, the delivery of products or services to end customers takes place. Distribution logistics is a complex process that involves the planning and coordination of various activities, such as transportation, inventory management, selection of delivery routes and returns management. It is important that appropriate technologies such as order tracking systems and GPS are used to manage deliveries. Good management of this phase can improve customer satisfaction, reduce distribution costs and improve overall supply chain efficiency. In addition, proper returns management can also improve customer satisfaction and ensure continuity of product and service flow in the supply chain.

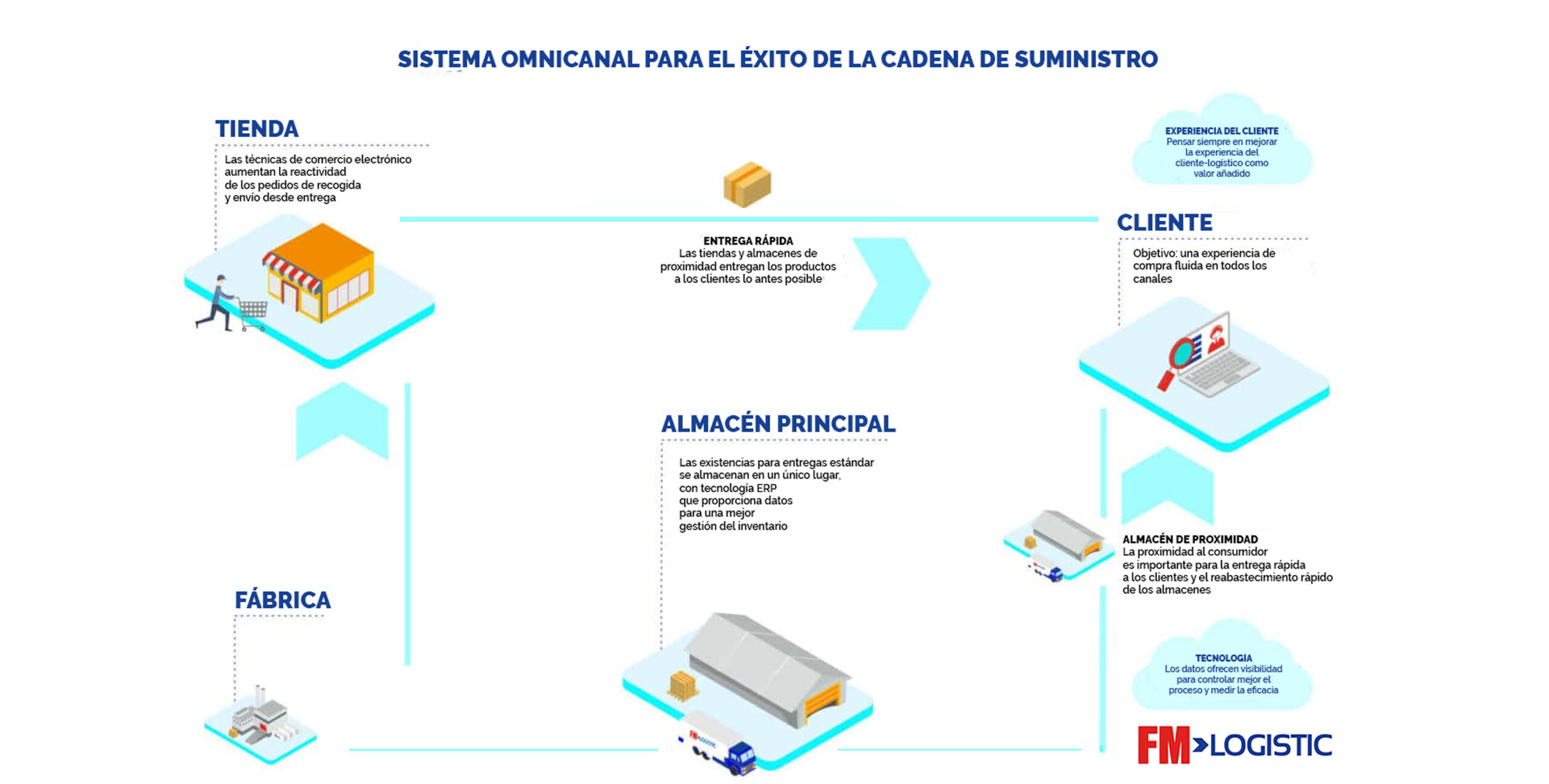

Omni-channel logistics refers to a company’s ability to efficiently integrate and coordinate all sales and distribution channels to meet customer needs anytime, anywhere.

Consumer-centric, omnichannel logistics creates a seamless selling experience. It doesn’t matter which channel the purchase is made through (whether in-store, mobile or web). However, synchronizing that shopping ecosystem requires supply chain innovation. A synchronization so that online and offline processes flow seamlessly. This gives retailers greater competitiveness and connection with consumers.

One of the most important technology tools for optimizing the omnichannel supply chain is the enterprise resource planning (ERP) system. ERP systems provide a complete, real-time view of the supply chain, enabling companies to make more informed decisions and improve coordination between different departments. By integrating information from different sales channels, ERP systems enable real-time inventory management, demand forecasting, production planning, and order and delivery management. In addition, ERP systems also offer the possibility of analyzing data and improving logistics processes on an ongoing basis.

Another key factor in optimizing an omnichannel supply chain is flexibility. To achieve this, companies must implement ecommerce techniques and adapt their logistics processes to the needs of each sales channel. In this regard, it is important for companies to offer multiple delivery and pickup options, such as home delivery, in-store delivery or pickup at a drop-off point. It is also important for companies to have the ability to adapt logistics based on demand and sales peaks. To do this, they can use techniques such as dropshipping or cross-docking to reduce delivery times and improve supply chain efficiency.

Proximity to buyers is another essential factor in optimizing an omnichannel supply chain. To this end, it is important for companies to be present in the sales channels most used by customers, such as online stores and social networks. In addition, companies must also take into account the geographical location of their customers to optimize delivery times and reduce logistics costs. In this sense, the implementation of warehouses close to end customers, known as dark stores, can be an effective strategy to improve supply chain efficiency and reduce delivery times.

Another important factor in optimizing an omni-channel supply chain is the partnership with the company’s marketing department. Marketing plays a key role in understanding market needs and demands, as well as identifying trends and opportunities in the environment. In this way, working closely with the marketing department enables the supply chain to anticipate market needs and adapt quickly to changes in demand. In addition, marketing can also provide valuable information on customer perception of the quality of products and services, which can be used to improve the quality of the overall supply chain.

An additional way to optimize the supply chain is by implementing a control tower, also known as an Operations Control Center (OCC). This control tower acts as a nerve center where real-time data is collected and analyzed for the entire supply chain, from the receipt of raw materials to the final delivery of the product or service to the customer. The control tower enables greater coordination and collaboration between the different departments and suppliers involved in the supply chain, leading to greater efficiency and improved responsiveness to changes in demand and the business environment. In addition, the control tower can also help detect potential risks and problems in the supply chain, enabling immediate action to avoid delivery disruptions and improve service quality.

If you are looking for a complete solution for the management of your supply chain, FM Logistic is your ideal partner. With more than 50 years of experience in logistics management, we have a team of experts in the field, a wide network of warehouses and our own fleet of vehicles to carry out transport and distribution operations. In addition, we offer value-added services, such as temperature-controlled storage, returns management and order customization, among others. All of this is backed by state-of-the-art technology that allows us to provide agile and efficient supply chain management. Trust FM Logistic to optimize your supply chain and take your business to the next level.

How can we help you ?

Fill in the form